- Bahrain Steel

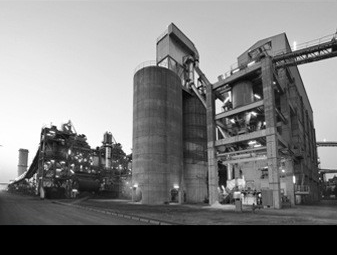

Bahrain Steel: Established in 1984, Bahrain Steel, wholly owned by Foulath, is a leading producer of iron-ore pellets used in the production of steel. It operates two pelletizing plants in the Kingdom of Bahrain with a total capacity of 12 million tons per year. It is the largest DR merchant pelletizing producer in the world and the only one located in the Middle East.

Bahrain Steel: Established in 1984, Bahrain Steel, wholly owned by Foulath, is a leading producer of iron-ore pellets used in the production of steel. It operates two pelletizing plants in the Kingdom of Bahrain with a total capacity of 12 million tons per year. It is the largest DR merchant pelletizing producer in the world and the only one located in the Middle East. - SULB

SULB Company B.S.C.:

SULB Company B.S.C.:

In 2009, Foulath formed SULB as a joint venture with the Japanese steel industry Yamato Kogyo and opened its DRI and heavy steel production plant in Bahrain. It acquired a light-to-medium rolling mill in Jubail, which became SULB Saudi Arabia. The two parts of SULB meet the region’s needs for steel sections, with exports made further afield. It is the Middle East region's first fully integrated medium and heavy beams and structural steel sections producer. - Foulath Infotech

Foulath Infotech: In 2019, Bahrain Steel and its sister companies from the Foulath Group engaged in an all-out commitment to a state-of-the-art digitalization transformation programme. Welcome to the start of a new era. Welcome to Foulath 4.0

Foulath Infotech: In 2019, Bahrain Steel and its sister companies from the Foulath Group engaged in an all-out commitment to a state-of-the-art digitalization transformation programme. Welcome to the start of a new era. Welcome to Foulath 4.0

| SULB |

|

SULB Company BSC (Closed)Â is the Middle East region’s first fully integrated medium and heavy beams and structural steel sections producer. Located in the Kingdom of Bahrain, SULB is a joint venture between Foulath Holding BSC (Closed), the Middle East’s leading steel investment vehicle and holding company (owning 51% of SULB), and Japan’s Yamato Kogyo Co., Ltd, a leading global beams and structural sections producer (owning 49% of SULB). SULB’s facilities are being established within Foulath’s existing state-of-the-art steel production complex located in Bahrain’s Hidd Industrial Area. SULB will be the lowest cost producer of its kind in the world and, once fully operational, will replace approximately 14% of the current imports of medium and heavy beams and structural sections into the Middle East markets. The project is being developed in co-operation with world leading steel industry and technical partners.

To view the SULB Environmental & Health Evaluation Report, please click here

|